Guide to Powdered Metals and Their Uses

Chapters

- What are Metal Powder Products?

- Advantages of Powder Metallurgy

- What Powdered Metals are Used In Additive Manufacturing?

- How Powder Metal has Fueled Growth in the 3D Printing Industry

- How to Choose a Powder Metal Distributor

- Mayer Alloys

What are Metal Powder Products?

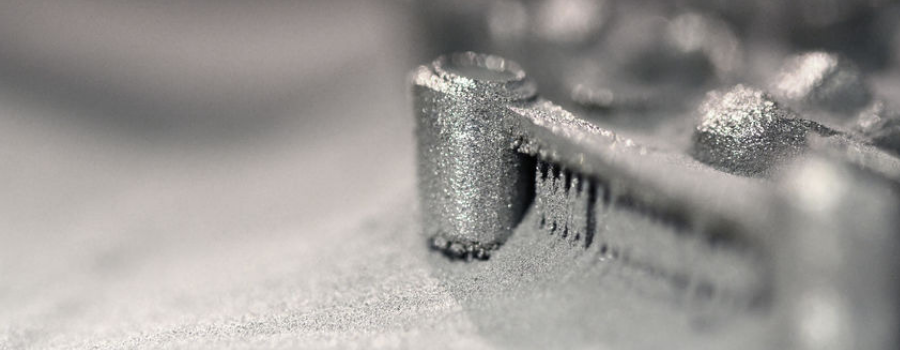

Metal powder products are created using powder metallurgy with a variety of processes including:

- Powder forging

- Hot isostatic pressing

- Metal

injection - Electric current assisted sintering

- Additive manufacturing (3D printing, selective laser sintering etc.)

Products made from powdered metals are ones that need to be made with more precision than the traditional manufacturing processes can produce. Examples are automotive or aerospace parts or other parts required is manufacturing, such as gears, turbine discs or medical devices.

Powdered metals are often used to facilitate lubrication, corrosion resistance or to create alloys.

Metal powders commonly used in manufacturing products:-

Aluminum Powder

-

Bismuth Powder

-

Cadmium Oxide Powder

-

Granular Copper

-

Iron Powder

-

Manganese Powder

-

Nickel Powder

-

Red and Black Cupric Oxide

-

Tin Powder

-

Zinc Powder

Advantages of Powder Metallurgy

Powder Metallurgy - Like Alchemy, Only No Magic Needed

There are many advantages to using powder metallurgy, but is it really the best solution for your project? Powder metal can be applied as a coating or used as the layers of 3D-printed-objects. Powder metal can also be integrated into a single step in the manufacturing process, or used from start to finished product.

While not all metals can be made into powder, mixes of powder metals, lubricants, and bonding-additives allow designers to create a wide array of highly customized, multi-dimensional parts and products ranging from fine meshes and thin-walled components to baking ware and metal plating.

What Powdered Metals are Used In Additive Manufacturing?

The call for 3D printing, also known as additive manufacturing (AM), is on the rise because it brings flexibility, customization, speed and reduced costs to manufacturing. 3D printing can produce objects from a variety of materials including photo-polymeric resins, extruded filament, powders of plastics and pure metals and alloys.

Metal additive processes such as metal powder bed fusion and directed energy deposition are potentially capable of producing high-quality, functional and

SLM and DMLS can produce parts from a large range of metals and metal alloys including:

- Aluminum

- Stainless steel

- Titanium

- Cobalt chrome

- Nickel

These materials cover the needs of most industrial applications, from aerospace to medical.

How Powder Metal has Fueled Growth in the 3D Printing Industry

Powder metal has been used extensively and with great success in the automotive industry. More applications are being discovered for powder metal every day, though, which makes it a near certainty that the adoption of powder metal will continue to shape and drive the growth of many non-automotive industries for years to come.

If you are wondering how other industries might be transformed by the adoption of powder metals, you might be able to catch a glimpse of the future by looking at how powder metal has the fueled growth of the 3D printing industry. Read More.

How to Choose a Powder Metal Distributor

Basic Criteria for Distributor Selection

When choosing a powder metal distributor, there are some basic and industry-specific questions to ask. Here are some tips on how to prioritize your selection criteria, starting with some basics:

- Are they used by competitors, or highly recommended by industry leaders?

- Are they known for their reliably excellent customer service?

- Are they known for timely delivery with appropriate packaging?

- Do they uphold the highest industry standards for quality and safety?

Industry-Specific Criteria for Distributor Selection

Additional criteria for choosing a powder metal distributor may vary by industry and organizational needs. Here are some examples of specific criteria that may be important to you in choosing a distributor. Read More.

Mayer Alloys

Mayer Alloys stocks a full line of the highest quality, non-ferrous metals specializing in finished metals including powdered metals, solder, tin and lead-based alloys, and lead-free alloys for manufacturing and/or fabrication. We are located in the Detroit Metro Area and supply powdered metals all over in country including Warren, Ann Arbor, Grand Rapids, Flint, and Chicago. As the Master Distributor for AIM Solder, all material we stock and supply is guaranteed and certified to comply with ISO 9001 standards.

We will ship your items the same day it is ordered in most cases. Customer service and technical assistance are always available to ensure you are getting the right materials. For technical support, please contact us at 888-513-7971 or email us at sales@mayeralloy.com.