Lead-free solder has become standard in electronic companies and manufacturers because of how hazardous lead can be. The Restriction of Hazardous Substances directive is more commonly known in the electronic industry as (RoHS) came into effect prohibiting the use of lead in consumer electronics produced in the EU. In the US, manufacturers may receive tax benefits by reducing the use of lead-based solder. The RoHS directive is aimed at restricting the use of 6 hazardous materials in the manufacture of electrical and electronic devices:

- Lead

- Mercury

- Cadmium

- Hexavalent Chromium

- Polybrominated Biphenyls

- Polybrominated Diphenyl Ether

Lead is poisonous and it can build up in the body due to many small exposures over many years. Lead can be can enter your body through your skin, it can also be inhaled or ingested. Lead has been removed from paint and gasoline, solder is one of the last common products that contains lead.

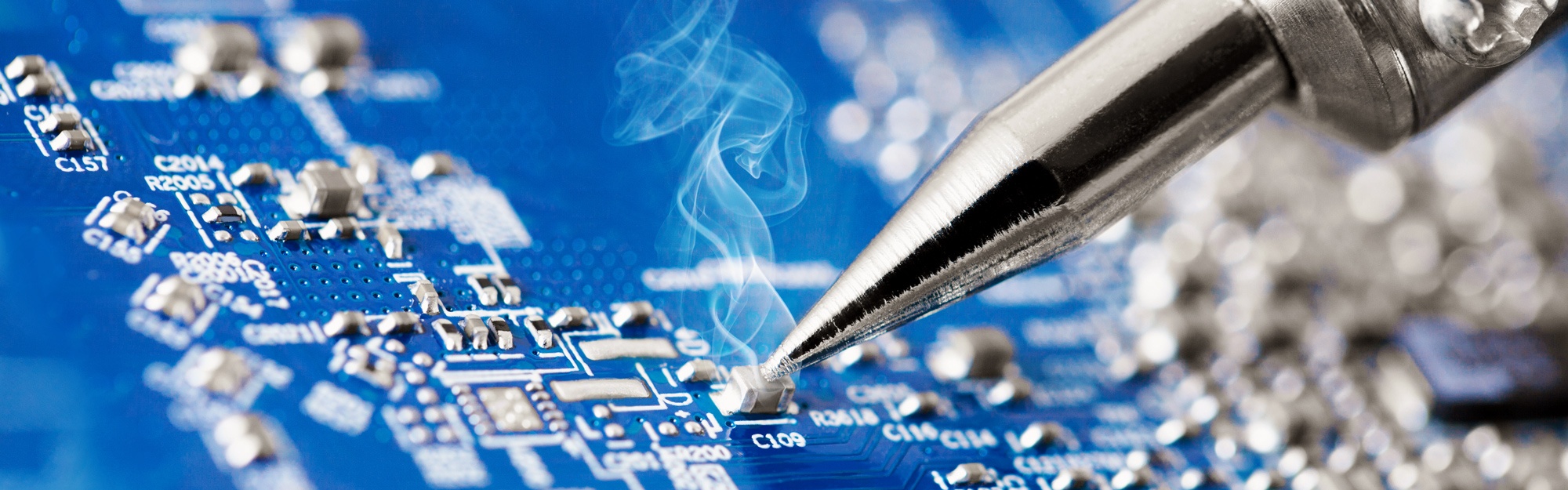

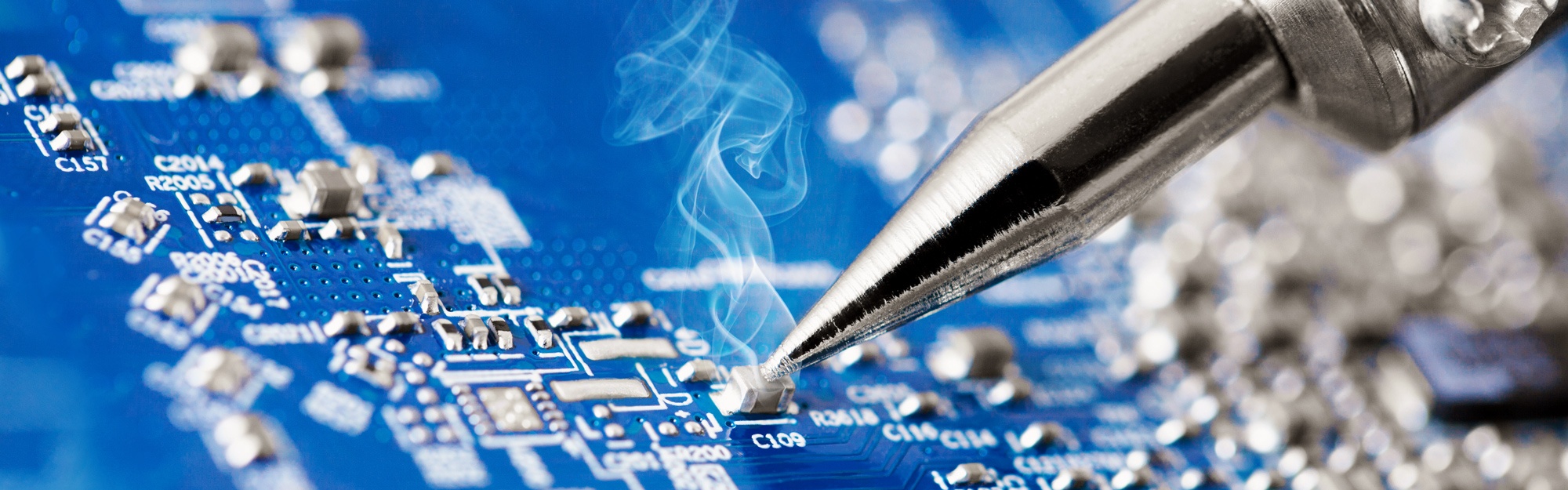

Prior to lead-free solder becoming standard among consumer manufactured goods, the use of tin/lead solder was widely accepted. Virtually all electronic assemblies were designed to withstand manufacturing with the use of tin/lead solder and the temperatures required. Lead-free solders in commercial use may contain tin, copper, silver, bismuth, indium, zinc, antimony, and traces of other metals. Most lead-free replacements for conventional 60/40 and 63/37 Sn-Pb solder have melting point from 5 to 20 °C higher, though there are also solder with much lower melting points. This has forced manufacturers to make design and process changes on products that were traditionally tin-lead based.

Many people were afraid that lead-free solder won’t last as long and products may fail. Lead-free solder may be less desirable for critical applications, such as aerospace and medical projects because its properties are less thoroughly known. As lead-free solder becomes more popular and required then we shall see if it will last the test of time.

Mayer Alloys

Mayer Alloys is a solder distributor that stocks and supplies a complete line of solder. All material we stock and supply is guaranteed and certified to comply with ISO 9001 standards. Mayer Alloys stocks a full line of the highest quality, non-ferrous metals specializing in tin and lead-based alloys, and lead-free alloys for manufacturing and/or fabrication. We will ship your items the same day it is ordered in most cases. Customer service and technical assistance are always available to ensure you are getting the right materials. For technical support, please contact us at 888-513-7971 or email us at sales@mayeralloys.com.

{{cta(‘0530d76d-2aa5-4bc8-bd94-5ec238270062′,’justifycenter’)}}

These are just some of the things you should know about solder. To learn more about solder download our Guide to Purchasing Solder to get more comprehensive knowledge on solder and details of all your soldering needs. If you have specific requirements, please contact us at 888-513-7971 or email us at sales@mayeralloys.com. We provide FREE technical assistance and will be happy to answer any questions you may have.

{{cta(’84b6dfbf-7635-4983-85ab-23e93d9819d4′,’justifycenter’)}}