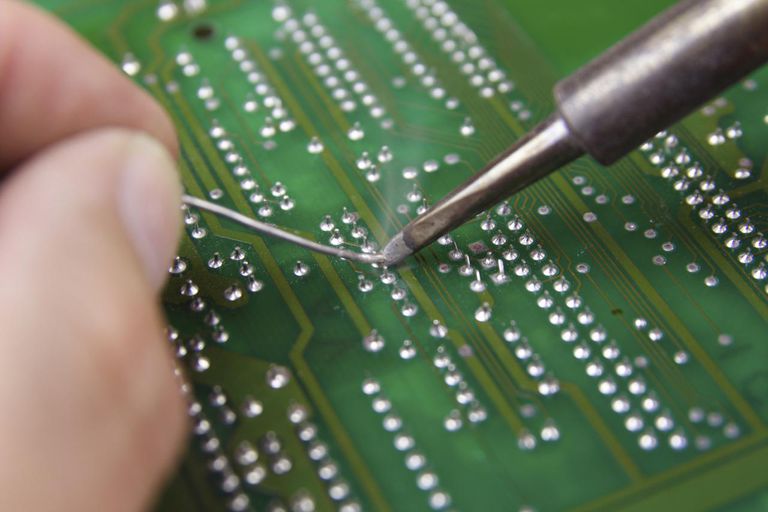

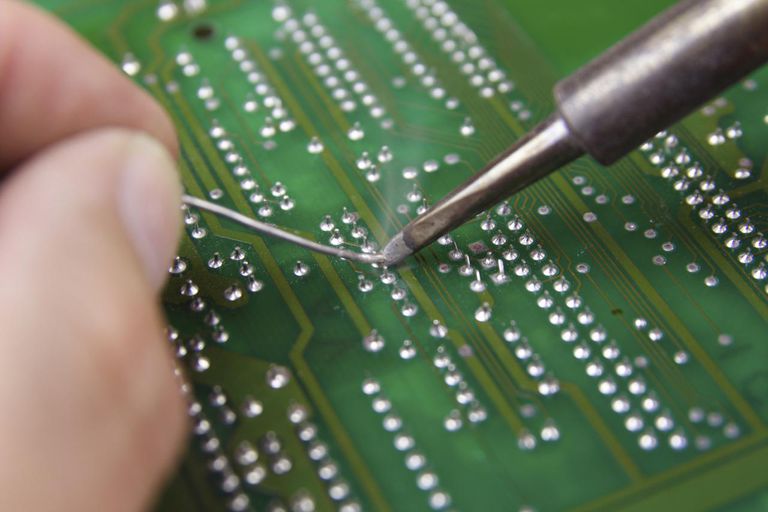

Solder Wire is one of the most popular forms of solder that is sold. It is used in many of the industries in which solder is used. Not all the solder wires are created equal- different wires are suited to different applications and temperatures. The solder wire can also vary drastically depending on the type of solder you are interested in purchasing.

Solder wires are wires with a low melting point which can melt along with the soldering iron. Depending on the application and soldering temperature, many different types of soldering wires are available..jpg) Solder wires are generally two different types – lead alloy solder wire and lead-free solder. There are also rosin-core solder wire which has a tube in the center of the wire that contains the flux. Lead solder wire is usually made from an alloy of lead and tin. Tin is commonly used with lead as it has a lower melting temperature. It has an alloy ratio of 63/37 or 60/40. When working with electrical components 63/37 is the best. This means that this solder wire has a sharp transition between solid and liquid states when the temperature changes. This property is very useful for reducing cold joints which usually happens when the components move while cooling.

Solder wires are generally two different types – lead alloy solder wire and lead-free solder. There are also rosin-core solder wire which has a tube in the center of the wire that contains the flux. Lead solder wire is usually made from an alloy of lead and tin. Tin is commonly used with lead as it has a lower melting temperature. It has an alloy ratio of 63/37 or 60/40. When working with electrical components 63/37 is the best. This means that this solder wire has a sharp transition between solid and liquid states when the temperature changes. This property is very useful for reducing cold joints which usually happens when the components move while cooling.

In the past lead-based solder has been an industry standard, although the health problems associated with lead had made it a less popular choice. As a result the lead solder wire and lead solder bar price have reduced over the past few years.

It is essential to understand your soldering requirements when selecting a soldering wire to make sure that the purchase effectively suits your application. In plumbing some of the solder used is 95Sn/5Sb, and 97Sn/3Cu. Some examples of materials used in this industry include 15Sn/85Pb, 20Sn/80Pb, 30Sn/70Pb, 25Sn/65Pb and 40Sn/60Pb as well as aluminum and copper. It is recommended in the stained glass industry to get 60Sn/40Pb but you can also use 50Sn/50Pb and 63Sn/37Pb depending on what you are working on. Rosin and acid core solder is also commonly used in electric circuit or electrical connections.

Learn more about solder wire and Mayer’s other solder alloy offerings here.

Mayer Alloys

Mayer Alloys is a solder distributor that stocks and supplies a complete line of solder. All material we stock and supply is guaranteed and certified to comply with ISO 9001 standards. Mayer Alloys stocks a full line of the highest quality, non-ferrous metals specializing in tin and lead-based alloys, and lead free alloys for manufacturing and/or fabrication. We will ship your items the same day it is ordered in most cases. Customer service and technical assistance is always available to ensure you are getting the right materials. For technical support, please contact us at 888-513-7971 or email us at sales@mayeralloys.com.